How to gain the Clear Writing Club’s Seal of Approval using AI

- Draft your article and run it through StyleWriter to see your Clarity Index

- Copy and paste the text it into Microsoft’s AI Copilot and ask for a plain English Redraft.

- Copy the Copilot redraft and run it through StyleWriter to see your improved Clarity Index.

- Follow StyleWriter’s advice to reach 75 on the Clarity Index.

- Award your writing the Clear Writing Club’s Seal of Approval.

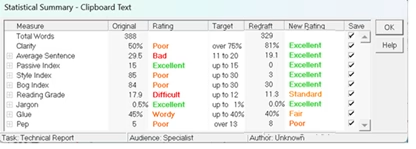

The dramatic change AI and StyleWriter can make to your writing style. Below is an example of how Copilot can improve a working document- which itself is then improved by StyleWriter.

|

Original |

Copilot 1st Plain‑English Redraft |

| A lead time is the latency between the initiation and completion of a process. For example, the lead time between the placement of an order and delivery of new cars by a given manufacturer might be between 2 weeks and 6 months, depending on various particularities. One business dictionary defines “manufacturing lead time” as the total time required to manufacture an item, including order preparation time, queue time, setup time, run time, move time, inspection time, and put-away time. For make-to-order products, it is the time between release of an order and the production and shipment that fulfill that order. For make-to-stock products, it is the time taken from the release of an order to production and receipt into finished goods inventory.

Supply chain management A conventional definition of lead time in a supply chain management context is the time from the moment the customer places an order (the moment the supplier learns of the requirement) to the moment it is ready for delivery. In the absence of finished goods or intermediate (work-in-progress) inventory, it is the time it takes to actually manufacture the order without any inventory other than raw materials. The Chartered Institute of Procurement & Supply identifies “total lead time” as a combination of “internal lead time” (the time required for the buying organization’s internal processes to progress from identification of a need to the issue of a purchase order) and “external lead time” (the time required for the supplying organization’s processes, including any development required, manufacture, dispatch and delivery). Manufacturing In the manufacturing environment, lead time has the same definition as that of Supply Chain Management, but it includes the time required to ship the parts from the supplier. Shipping time is included because the manufacturing company needs to know when the parts will be available for material requirements planning purposes. It is also possible to include within lead time the time it takes for a company to process and have the part ready for manufacturing once it has been received. The time it takes a company to unload a product from a truck, inspect it, and move it into storage (“put-away time”) is not trivial. With tight manufacturing constraints or when a company is using Just In Time manufacturing, it is important for supply chain to know how long their own internal processes take. |

Lead time is the amount of time between starting a process and finishing it. For example, if you order a new car, the lead time is how long it takes from placing the order to receiving the car. Depending on the manufacturer and the situation, this might be anywhere from two weeks to six months.

In manufacturing, “lead time” usually means the total time needed to make a product. This can include preparing the order, waiting in queues, setting up machines, actual production time, moving items around, inspecting them, and putting them into storage. · For products made only after an order is placed (“make‑to‑order”), lead time is the time from releasing the order to producing and shipping the item. · For products kept in stock (“make‑to‑stock”), lead time is the time from releasing the order to finishing production and adding the item to inventory. Supply Chain Management In supply chain terms, lead time is the time from when a customer places an order to when the product is ready to be delivered. If there are no finished goods or work‑in‑progress items available, this lead time is simply the time it takes to manufacture the product using only raw materials. The Chartered Institute of Procurement & Supply breaks “total lead time” into two parts: · Internal lead time: how long it takes the buying company to go from identifying a need to issuing a purchase order. · External lead time: how long the supplier takes to develop, make, ship, and deliver the product. Manufacturing In manufacturing, lead time is defined the same way as in supply chain management, but it also includes the time needed to ship parts from suppliers. This matters because manufacturers need to know exactly when parts will arrive so they can plan production. Lead time can also include the time it takes a company to unload incoming materials, inspect them, and store them properly. These steps—often called “put‑away time”—can be significant. When a company has tight production schedules or uses Just‑In‑Time manufacturing, knowing the length of these internal processes is especially important. |

| Copilot 1st Plain‑English Redraft Clarity Index 70 (Good) Style Issues 14 344 words |

StyleWriter Redraft Clarity Index 81 (Excellent) Style Issues 1 329 words |

| Lead time is the amount of time between starting a process and finishing it. For example, if you order a new car, the lead time is how long it takes from placing the order to receiving the car. Depending on the manufacturer and the situation, this might be anywhere from two weeks to six months.

In manufacturing, “lead time” usually means the total time needed to make a product. This can include preparing the order, waiting in queues, setting up machines, actual production time, moving items around, inspecting them, and putting them into storage. · For products made only after an order is placed (“make‑to‑order”), lead time is the time from releasing the order to producing and shipping the item. · For products kept in stock (“make‑to‑stock”), lead time is the time from releasing the order to finishing production and adding the item to inventory. Supply Chain Management In supply chain terms, lead time is the time from when a customer places an order to when the product is ready to be delivered. If there are no finished goods or work‑in‑progress items available, this lead time is simply the time it takes to manufacture the product using only raw materials. The Chartered Institute of Procurement & Supply breaks “total lead time” into two parts: · Internal lead time: how long it takes the buying company to go from identifying a need to issuing a purchase order. · External lead time: how long the supplier takes to develop, make, ship, and deliver the product. Manufacturing In manufacturing, lead time is defined the same way as in supply chain management, but it also includes the time needed to ship parts from suppliers. This matters because manufacturers need to know exactly when parts will arrive so they can plan production. Lead time can also include the time it takes a company to unload incoming materials, inspect them, and store them properly. These steps—often called “put‑away time”—can be significant. When a company has tight production schedules or uses Just‑In‑Time manufacturing, knowing the length of these internal processes is especially important. |

Lead time is the time between starting a task and finishing it. For example, if you order a new car, the lead time is the time from placing the order to delivery. Depending on the manufacturer and the circumstances, this time may vary from two weeks to six months. In manufacturing, “lead time” usually means the total time needed to make a product. This can include preparing orders, waiting in queues, setting up machines, assembly time, moving items, inspecting them, and storing them. · For products made after the customer places an order (“make‑to‑order”), lead time is the time from taking the order to producing and shipping the item. · For products kept in stock (“make‑to‑stock”), lead time is the time from releasing the order to finishing production and adding the item to inventory. Supply Chain Management In supply chain terms, lead time is the time from when a customer places an order to when the product is ready for delivery. If no finished goods or work-in-progress items are available, this lead time is the time taken to make the product using only raw materials. The Chartered Institute of Procurement & Supply breaks “total lead time” into two parts: · Internal lead time: how long it takes the buying company to go from identifying a need to issuing a purchase order. · External lead time: how long the supplier takes to develop, make, ship, and deliver the product. Manufacturing In manufacturing, lead time is the same as in supply chain management, but it also includes the time needed to ship parts from suppliers. This matters because manufacturers need to know exactly when parts will arrive so they can plan production. Lead time can also include the time it takes a company to unload incoming materials, inspect them, and store them properly. These steps – often called “put‑away time” – can be significant. When a company has tight production schedules or uses Just‑In‑Time manufacturing, knowing these internal times is essential. |

Membership details and Join the Clear Writing Club

Clear Writing Club – promoting excellence in academic, business and government writing style.

You must be logged in to post a comment.